The climate is changing inside control cabinets

LÜTZE supply a highly innovative product family, comprised of the AirSTREAM wiring system, the AirTEMP heat analysis software and the new LÜTZE AirBLOWER, for efficient air conditioning in control cabinets.

When LÜTZE launched the AirSTREAM wiring system a few years ago, it represented a revolutionary approach: the passive control cabinet cooling methods alone allow the temperature in the cabinet to be reduced. In specific industrial applications, the use of the LÜTZE AirSTREAM wiring system is even possible without an external cooling unit. The LÜTZE AirSTREAM concept has now established itself in the market. Lots of practical experience and scientific studies prove its efficiency. But LÜTZE has not stopped its research and development efforts. The engineers at LÜTZE Cabinet Solutions have consistently continued to expand the AirSTREAM wiring system product family. At the start of 2016 the webbased AirTEMP configurator was made available to allow an in-depth analysis of the heat build-up and distribution in the control cabinet for the first time. This 'heat forecast' is more impressive than a simple description of the actual status, it allows the various heat build-up situations in the control cabinet to be calculated in advance. This means that future heat build-up can be determined during the design phase. The latest member of the AirSTREAM product family is the LÜTZE AirBLOWER. The AirBlower balances out the air layers in the control cabinet and significantly improves the heat control in the AirSTREAM control cabinet. The results of practical tests have been outstanding. With the AirBLOWER it is possible to reduce the average temperature in the control cabinet by up to 10K.

Passive control cabinet air conditioning now has widespread recognition by control cabinet designers.

There were many questions when the AirSTREAM control cabinet system was launched: "Can it work?" or "Can it replace active air conditioning inside the control cabinet?" First of all, it is NOT the aim of the LÜTZE AirSTREAM family to replace active air conditioning measures, such as, roof cooling or front mounted cooling systems - the focus is more on minimising and balancing the heat level in the control cabinet to the extent that external cooling can be significantly reduced. In some cases, it is possible to do without an external cooling system completely. The results of the Green Carbody Alliance, a scientific initiative under the leadership of Volkswagen AG, verify that energy savings of up to 23 % can be achieved using the LÜTZE AirSTREAM control cabinet system.

LÜTZE AirBLOWER utilises the potential of the AirSTREAM

The LÜTZE AirBLOWER makes use of the positive effects of the AirSTREAM wiring frame, its optimised air circulation and the 'chimney effect’. This has been impressively proven by the following test.

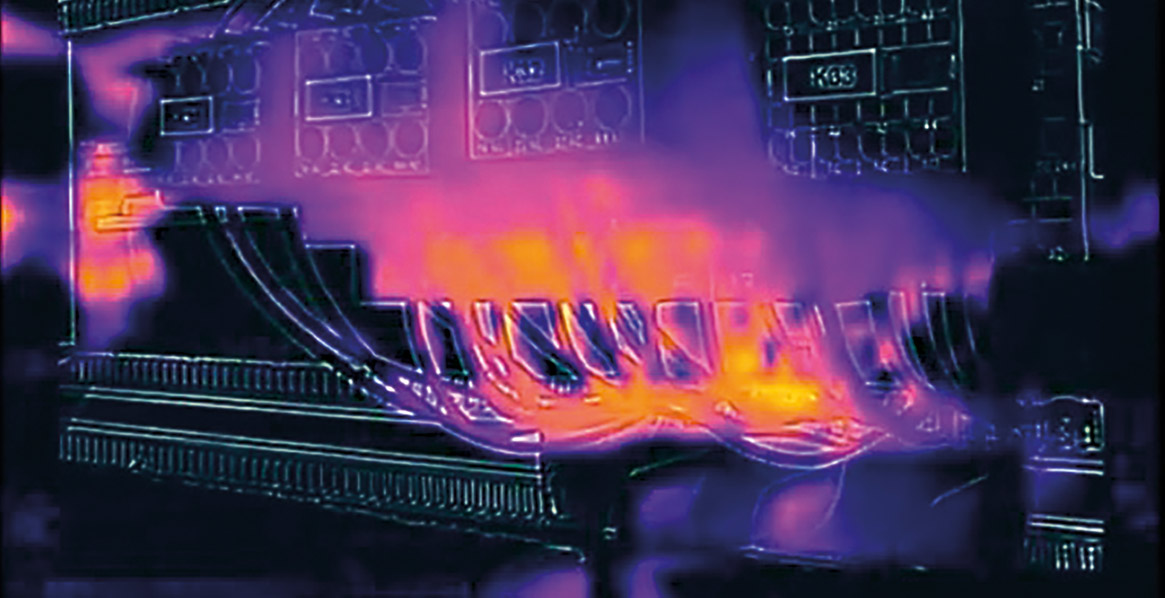

The study shows various thermal images from inside an AirSTREAM control cabinet in fast motion. The power components inside the control cabinet itself are installed with corresponding heat build-up. There was no active cooling used in the test.

As shown in Fig. 1. the average heat level in the control cabinet is in the normal temperature range at the start of the test. The warm areas around the power components are clearly shown. The yellow or white areas are those areas with the highest temperature. Blue and violet areas stand for cooler zones. The power components in the lower area of the image do generate a relatively high level of heat, however the overall level in the control cabinet is at an acceptable level.

Fig. 2 shows inside of the control cabinet about 80 minutes later. The picture has changed dramatically. A hotspot has formed around the power components. Sooner or later the power electronics will become damaged. The heat level throughout the control cabinet is much higher and now threatens the components.

This is the phase in which the LÜTZE AirBLOWER in the control cabinet is switched on.

Fig. 3 shows inside of the cabinet just 8 minutes after the LÜTZE AirBLOWER was started. It only took 8 minutes to reduce the average heat level in the control cabinet to a reasonable level. It was possible to eliminate all hotspots around the power components completely.

Two that belong together

LÜTZE AirBLOWER and LÜTZE AirSTREAM wiring frameThe advantages of the LÜTZE AirBLOWER are obvious. Within just a few minutes the temperature level in the control cabinet can be evened out and reduced by up to 10K. It should also be taken into account here that operating the LÜTZE AirBLOWER requires much less energy than an active cooling unit.

Also, the AirBLOWER does not need to be operated permanently, it can be activated in cycles. See Fig. 4

LÜTZE AirBLOWER

Simple assembly of the fan modules

LÜTZE supplies the 24 V fan modules that mount to the AirSTREAM rail in various lengths, e.g. 700, 900 and 1100 mm. Depending on the wiring concept, there are fan modules for various installation options which can be used for either maximum wiring space or wiring comfort.

The AirBLOWER modules are controlled via the AirBLOWER control unit LCOS-AB-I that allows freely configurable operation of the fans.